I forgot to submit my week 6 blog earlier, but I wanted to capture the unique work done during this week from July 2nd through 7th! Although I didn’t go anywhere outside of San José, but I was able to make progress on various projects as well as get further on my graduation plans in applying to medical school as I focused on completing some essays when I wasn’t working or training. The week started by working on these applications while also going into the hospital over the weekend so that we could finally get the fancy EMG and motion sensing equipment that Dr. Vargas has to try to get baseline readings for a device that we would employ.

We bought many electrical and mechanical components, printed more components in various materials, and I was able to continue clinical observations. Specifically, after reaching out to a contact from ULACIT, we not only got help with design ideas, but we also were able to obtain expensive components like linear actuators and EMG sensors to allow us to test these products without having to spend Dr. Vargas’ money. With Dr. Vargas, I printed hand components in PLA and in a more flexible filament for multiple different hand models to determine how their assembly could accommodate an electromechanical design with motors. Dr. Vargas also worked with me help me learn Fusion360 basics, which I am continuing to learn by myself as time allows.

The unassembled Phoenix components that I scaled and printed.

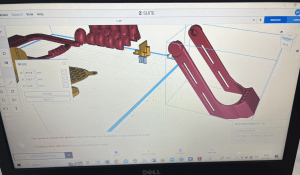

Scaling and orientation in Zortrax of arm pieces we may want to modify or attach to in the Phoenix hand design.

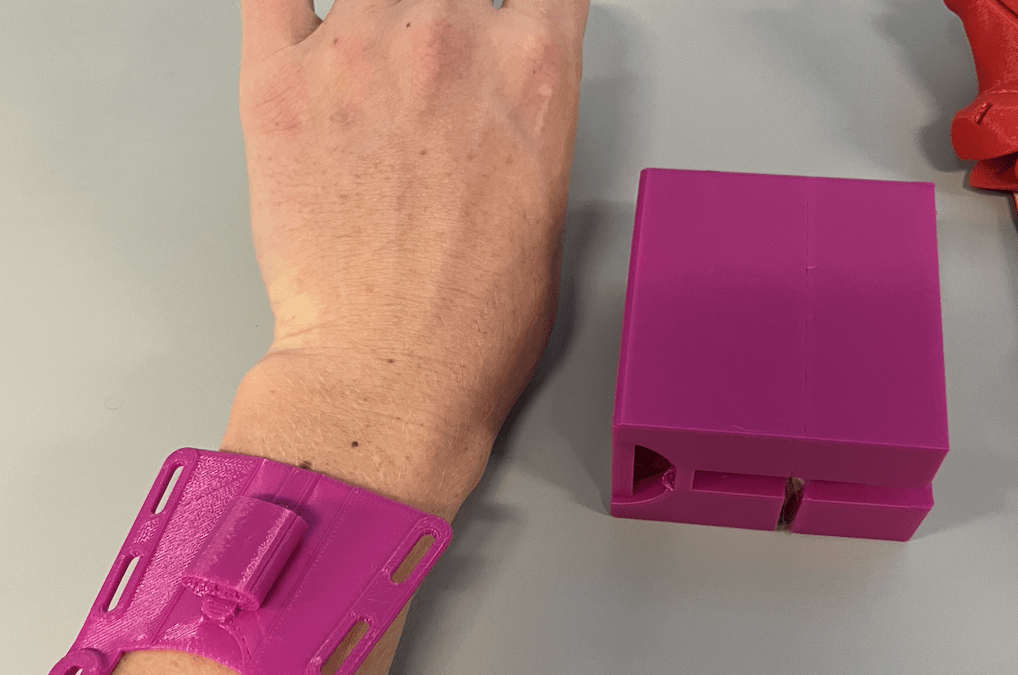

When Dr. Vargas and I had printed these components, we printed some test components to visualize ways that we might be able to put an electronics box onto the different hand designs off of which we were working. I also used low fidelity prototyping to visualize how this would work to hold all of the electronic components based on different design conceptions I had.

Low fidelity prototyping of how the electronics such as the batteries might connect to the hand that I printed.

initial design of a possible slide-on component housing electronics. We would need to scale this to allow it to contain all components without being excessively bulky.

Although I will be traveling for much of the next week, I believe I have set myself up well to continue progressing on the project virtually.

Unfortunately, my knee is still injured, which has made my experience a bit less fun. I am continuing to work through this injury with important rehab work and lots of cross training to stay in shape.