Group photo of GMI cohort!

Another week done and another experience had! Tuesday through Friday this week has been spent at UCIMED (Universidad de Ciencias Medicas) in San Jose participating in the Medical Innovation bootcamp (photo alert!). I was not sure what to expect going into this week other than long days, however it turned out to be a highly worthwhile experience. Our days were a mix of lectures on various aspects of the engineering design process, from needs finding through concept selection to manufacturing considerations, and time to work in our teams to complete those aforementioned components for our specific team’s project. It was very collaborative and interactive which helped keep the students attending (Rice and Costa Rican alike) engaged throughout the week. On top of everything happening during the 8-5 workday, lots of memories were also made over breakfast, lunch, dinner, and beyond with those in the GMI cohort!

Medical Innovation Bootcamp

My team, deTENSify, was pitched the problem that a number of workers in demanding jobs (including nurses) are at high risk for developing chronic foot pain, and transcutaneous electrical nerve stimulation (TENS) has been proven to relieve that pain in many cases. We were tasked with developing a sock or something to fit under which would be able to provide TENS therapy during the workday while the user is standing. With our limited knowledge of this technology, we began the research phase with compiling the questions we’d need answered to move forward. These questions were in categories including: background info, info on customers, applicable standards and regulations, potential technologies to be used in the design, and competitive products and patents. Our team prioritized the most relevant and important questions to dig into the research phase. Some of these questions related to optimal placement of TENS electrodes for foot pain, finding safety standards for electronic wearables, and looking into devices currently on the market. We next examined patient flow (how a patient progresses through treatment for a given disease state) and money flow (who is paying for the treatment) to better understand the problem and our target population.

Following initial research, we performed a Prevention, Diagnosis, Treatment (PDT) Analysis which looked at our various stakeholders and took into account their role in each category and the level of need in the given area. Our stakeholders were nurses (patient), workplace insurance (payer), and clinician (provider); the areas of highest need were patient diagnosis and patient and payer treatment, all relating to the ability of the patient to get the needed device and for insurance to cover that cost. We next moved into a market analysis, breaking down various segments within our potential markets and landing on a predicted financial outcome. Our targeted segment was acute care nurses with chronic foot pain in the US, and by multiplying estimated market size (1.2 million people), willingness to pay ($50), and predicted market share (16%), we predicted our financial opportunity for a TENS wearable to be $9.6 million/year.

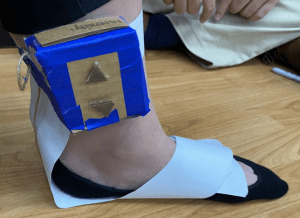

After defining the problem, population, and outcome in a need statement, we determined the objectives and constraints that would be necessary for project success. We next began the brainstorming process and started conceiving actual solutions to the problem of not having a viable way to treat chronic foot pain for acute care nurses during the workday. A Pugh Screening Matrix was used to objectively compare all of our ideas against a standard TENS therapy unit using the design criteria aforementioned and the winner was our Flex Wrap TENS therapy unit. We were then given time to produce a low-fidelity prototype, which we were able to do using paper, buttons, string, tape, and cardboard. The unwrapped model can be seen below and the steps to wrap it can also be seen to show how the continuous material can be placed on/around the foot and leg (photo alert!). Our team decided on a self-adhering material to decrease additional material costs while keeping high durability and flexibility. The buttons represent the electrodes, with one for the bottom of the foot and the second wrapping on top of the foot before getting secured by the next wrap flap. The second electrode is adjustable to make it more customizable for the user, allowing for proper placement no matter the size of the foot, which helps increase the market size for our concept. The battery pack on the leg slot is also adjustable so the user can decide where above the ankle it is most comfortable to have the pack, while also allowing the user to adjust the intensity of the pulses and read off that intensity value in real time.

Unwrapped prototype wrap.

Wrapped prototype.

Prototype wrapping steps.

Haruto, Sofia, Laurel and I with our poster at the symposium!

After prototyping, we completed a Labor, Burden, Material (LBM) analysis to analyze overall manufacturing costs then dug into current patents to determine a medium-low risk for patent infringement with our solution. We were able to share our designs and engineering process with judges and local sponsors at the Medical Innovation symposium on the final afternoon, and our team won awards from multiple sponsors for our work in the design challenge (yay!)(photo alert!). Overall, there was quite a bit of learning/refreshing on the engineering design process, as well as team project time which allowed us to progress through our projects using the skills we had discussed immediately prior. It was exciting to be recognized for our work as well, especially due to the high demands of the week and our pride for the deTENSify project.

Fun Extras

Uber view!

In other news, we had lots of fun moments as a cohort as well! Tuesday lunch was fries for Jhalak and I when our UberEats cancelled on us, and dinner was a SLICE of home with the whole group at Pizza Hut. We played some games and ended up sitting at the restaurant for hours laughing and playing games. Wednesday for dinner we went for homestyle Italian at Il Picolino, where I had a delicious four cheese linguine and Asma and I opted to get a homemade chocolate brownie for dessert! Following dinner was planning for our Saturday off (#volcanotime) and then bed. Thursday lunch was group leftovers of pizza and pasta, of which we had to scoop the pasta using bread since no utensils were in sight, and dinner at Cosi, where we were able to lay off the carbs for a meal with soups and salads. These leftovers became Friday lunch, and after a celebratory Pops ice cream run after the end of the medical innovation bootcamp, we made our way to an Indian restaurant in the neighborhood where we were able to eat family style and try a variety of dishes. Another good week of food in my opinion, however, I am definitely ready to be cooking again which will happen in a couple days with the move from Hotel 1492 to Selina San Jose following the next bootcamp: Needs Finding at Clinica Biblica.

Until next time!