Wow! We are half-way through our internship, the time is flying! This week, I was able to work more on my project and made some significant progress, so that made the week go by even faster than normal. Aside from working on my project, I got to attempt to insert a urinary catheter, learn about neuromodulation, and come to some significant insights about biomedical engineering.

Let’s start with the insights: First, while reminiscing about my previous internships in the oil and gas industry, which is a world away from the medical realm, I realized that at the heart of it, most engineering jobs are extremely similar. All involve processes accompanied by paperwork, meetings to collaborate and share progress updates, various projects that must be balanced, information gathering to understand possible solutions, and most importantly, sound decision making based on technical knowledge. All external factors aside like company culture and coworkers, the thing that differentiates between engineering jobs is the projects themselves. So it is extremely important to be interested in the products that you are working on. Currently, I’m not sure exactly what products I’m most interested in, but I do know that they reside in the medtech industry. My second insight involved quality systems. Basically, a quality system is a framework of checks and structured processes that guide all work in a company. Initially, while reading through my mountain of training paperwork, I thought that quality systems only slowed work down and made everything more laborious due to extra paperwork and hoops to jump through. However, I realized this week that quality systems are extremely important in the medical industry because patients’ lives are at risk. A quality system ensures that patient safety is safeguarded as best as possible. It catches small details that tend to fall through gaps (like new FDA standards or recently identified risks from products) that can have terrible consequences. It helps to maintain the company’s reputation by only allowing the highest quality of work. It also provides a way to track work to improve products and processes through good documentation. So although complying with a quality system can be frustrating, I am now convinced that it is absolutely necessary.

Honestly, I have been surprised at how much I have been learning in the past three weeks. I expected the learning curve to more or less level off at some point during my internship, but it hasn’t, a fact for which I am extremely grateful. The difference is that while I was learning just facts, now I am actually understanding by piecing the facts together to create a full picture. For example, I learned about quality systems, good documentation, and the product development process during training. But it was only this week that I understood that all three are actually inseparably intertwined. My project centers around ensuring FDA compliance to new guidelines, which was caught by the quality system. But without the product development team documenting their choices and specifications, I would not be able to learn about the products enough to even start my project. So it all comes full circle. I am coming full circle by understanding what the trainings I read actually mean in real life.

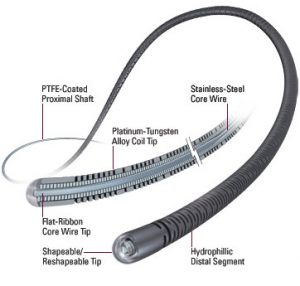

Speaking of learning, this week I was also privileged to participate in a urology clinical training. I learned about the different parts of the urinary system (kidneys, bladder, etc.) and how kidney stones are removed. Then, as always with the clinical trainings, I got to try my skills with real devices on a dummy setup. I was really glad that it was a dummy because I speared it about ten times until I hit the kidney stone while simulating the percutaneous (through the skin) approach to removing kidney stones. I wasn’t even able to get the catheter in the ureter tube in the other simulation with rubber organs and a scope camera. This is especially significant because I was “cheating” by using the shadow of the device to help me, moving the fake organs around in an attempt to succeed, and watching the screen that actually showed some contrast. All three of these are advantages that surgeons do not have in real life. So my respect for surgeons skyrocketed that day. They have skills beyond anything I can imagine; I tip my hat to you all.

Another highlight of my week was talking with the head of R & D neuromodulation (aka Chandler’s boss). He gave us a high-level view of neuromodulation which consists of sending electrical signals to nerves to decrease symptoms. It is absolutely amazing what they can do. With an implant, the tremors of Parkinson’s disease are stilled, crippling chronic pain fades to background noise, and the deaf can hear. It is an amazing field that I am looking forward to seeing what it has to offer in the next twenty years because they are just scratching the surface.

Here are more fun facts about Costa Rica:

- Holding the door open for others is common courtesy

- Costa Rica sits on the intersection of two tectonic plates, so small earthquakes are frequent

- Speed limit signs are rare in the city because traffic and speed bumps are the main speed regulators

To wrap up our week, we took a trip to Arenal volcano. It was a blast! We hiked the active volcano, swam in the clear lake, soaked in the natural hot springs, browsed local art, and enjoyed the ever-shifting weather.