Being a part of the Exploratory Phase team in Process Development has exposed me to a diversity of topics and projects happening on the Coyol site, making these past three weeks at Boston Scientific fly by! Although I have done a lot during my time, I still have much more work to do. I am also beginning to realize that Process Development engineers need to be very dynamic as they collaborate with both R&D and Manufacturing engineers A LOT, which I really enjoy piecing together each side’s perspective into a project.

Last week I spoke about my exploration of methods to utilize a new material for urethral stents and this week I hoped to solidify these methods in order to test it out. Fast forward to this week- I spent the beginning of the week reaching out to Manufacturing engineers to better understand the current processes they use. First off, I learned that Manufacturing engineers are very busy on the production line! Second off, these discussions led me to take one step back to focus on how to prepare the material because I found out the equipment I needed did not exist in our site. So I had to make it work somehow, but ideally with the tools I did have at my disposal. My meeting with one Manufacturing engineer set up how I will approach this preparation technique next week.

Regarding my other project in developing an R&D engineer’s design ideas into build plans, we were able to establish which configurations of the factors were most representative. This allowed me to formulate a document describing what parts were needed and the necessary parameters to build the prototypes. Following my planning, I reached out to a couple Manufacturing engineers who would be able to assist me in obtaining the materials for the prototypes. It was exciting to finally create my first draft of a deliverable in my project, as it meant I was one step closer to assembling the prototypes.

Both my projects were briefly put to a pause on Tuesday because for the next few days I worked with my team and a visiting R&D engineer from the Boston Scientific headquarters to complete a new project dealing with rotatable snares. This project has been in progress since I started three weeks ago and now it was being executed in order to carry out benchmark tests. Typically, a Process Development engineer will “rent” out a production line to carry out the assembly of a prototype they are working on. On Tuesday, we made our first attempt at carrying out the assembly of these rotatable snare prototypes on the production line, although a few logistics and the learning curve for the new product delayed the start of manufacture. Therefore, the next day my team and the visiting R&D engineer spent the whole morning and early afternoon building the first part of the prototypes in the engineering lab. It was important to have different people working on the assembly to simulate the variability on the production line. I was thrilled to have the chance to work with my hands and bring an idea to life! Through this process, I unfortunately learned about the strength of Loctite (a gap filler adhesive) and that it’s not the most enjoyable thing to get in between your fingers! We eventually formed over 100 prototypes that were later, on Wednesday and Thursday, completed on the production line. To finish up the project, on Friday I drafted up a document with instructions and pictures on how to form the main part of the prototype for future iterations because it was a bit of a finicky process. While I was not able to focus on my own projects this past week, in reality it would have involved a lot of waiting for responses and materials delivery. I also had the opportunity to converse more with an R&D engineer and learn more about their daily work schedules at Boston Scientific in the United States. It is very interesting to hear comparisons between different sites’ work culture and environments, even within the same company.

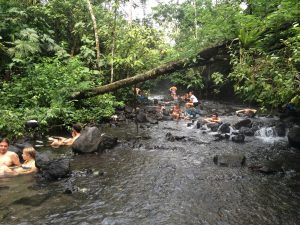

This weekend was not only a big weekend because it was our halfway point through the internship, but it also was our first whole weekend trip and we spent it at Arenal Volcano. Arenal is the mecca of ecotourism and it is absolutely crucial to make a trip out to one of the beautiful (and active!) volcanoes of Costa Rica. We took a 5 km hike around the lava beds surrounding Arenal Volcano and saw some small glimpses of Arenal Volcano itself, but for the most part it was covered by clouds. Even in its half covered state, you could only imagine its grandeur and fear-invoking presence on the town of La Fortuna. Not only did we visit for the volcano, but the La Fortuna area is also known for its multitude of hot springs- all the way from transformed and developed to natural and rugged. We got to experience both sides of the spectrum of hot springs, and I would say the natural ones were truly unique.

Until next time. Pura Vida.